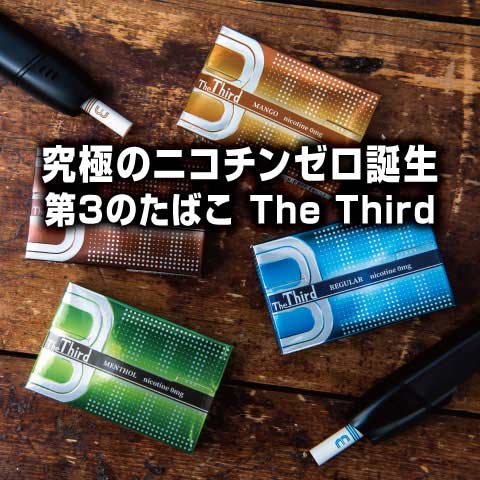

From Izumi City, Kagoshima Prefecture, to all across the nation, we deliver next-generation services driven by the latest technology. Our domestic production ensures reliability and safety, as we contribute to the realization of a sustainable society through our nicotine-free products.

From Izumi City, Kagoshima Prefecture, to all across the nation, we deliver next-generation services driven by the latest technology. Our domestic production ensures reliability and safety, as we contribute to the realization of a sustainable society through our nicotine-free products.

As our primary domestic manufacturing facility, we have a fully automated production factory found in Izumi City, Kagoshima Prefecture. The factory covers a site area of 13,460 square meters. Furthermore, the surrounding area includes approximately 20,000 square meters of employee housing, welfare facilities, and a planned parking lot. Future Technology has reached a location agreement with the city. With a focus on coexistence, we are actively promoting the localization of management, human resource development, and local procurement. As a member of the local community, we are engaged in activities that are deeply rooted in the community.

| Number of employees | 67 |

|---|---|

| Kagoshima Prefecture | |

| Izumi-city | 52 |

| Akune-city | 6 |

| Kagoshima-city | 1 |

| Nagashima-Cho | 1 |

| Minamata-city, Kumamoto Prefecture | 5 |

| Branch office in Tokyo | 2 |

| ※We have hired a significantly larger number of people than the original plan of thirty individuals and are actively involved in community contribution activities. In addition to Izumi City, we will also concentrate on recruiting in other areas of Kagoshima Prefecture, thereby contributing to job creation within the prefecture. | |

Future Technology manufactures and develops next-generation services and products with a focus on marketing. We use the latest patented and unique technologies to contribute to the realization of a healthy and sustainable society.

| Classification | Patents | Design | Trademark | Total |

|---|---|---|---|---|

| Number of applications | 246 | 26 | 18 | 290 |

| Number of surviving patents | 202 | 1 | 7 | 210 |

| Number of ongoing registration/ patents | 44 | 25 | 11 | 80 |

| Country of applications | Japan | PCT | China | Korea | Taiwan | Hong Kong | USA | Europe | Russia |

|---|---|---|---|---|---|---|---|---|---|

| Number of applications | 153 | 33 | 17 | 10 | 5 | 2 | 10 | 8 | 8 |

Izumi Factory, situated in Izumi City, Kagoshima Prefecture, has achieved ISO9001 and HACCP certification for the manufacturing of non-nicotine cartridges. ISO 9001 is an international standard for quality management systems aimed at improving the quality of products and services.

HACCP refers to an international method of managing hygiene to ensure food safety. Having received certification, we are implementing proper quality and hygiene management based on ISO 9001 and HACCP. We will continue to strive to make further contributions to the safety and security of our customers.